Filter Search Results

FAQ's

PWR Radiators

You will see three main advantages:

1. Performance. Superior radiator core design options to suit all applications.

2. Appearance. Aluminium radiators can be finished a raw material natural alloy, polished or powder coated black is also available on request.

3. Weight. Aluminium radiators are often one third of the weight of a conventional copper brass radiator. Anything that is physically lighter is thermally more effective at dissipating heat.

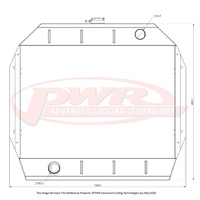

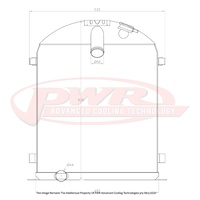

Most of PWR’s part numbers are a direct fit aftermarket performance upgrade designed to mount in the OE location. However, as these part numbers are a variation the OE part number, please check the product description and CAD drawing prior to placing your order. PWR also specialise in custom designed one-off pieces. We manufacture all of our products in-house at our Gold Coast facility including the core, so we have the flexibility to design and manufacture products to suit your requirements, contact us today.

The lighter aluminium is not the only reason for more efficient heat transfer. This is also achieved with the use of larger, wider tubes. This in turn means fewer wider rows. This promotes a larger rate of cooling airflow over the tubes, particularly at low vehicle speeds. This sees greater tube to fin contact, which is essential considering the fins do over 90% of the heat dissipation. So yes, you can use fewer rows with an aluminium radiator.

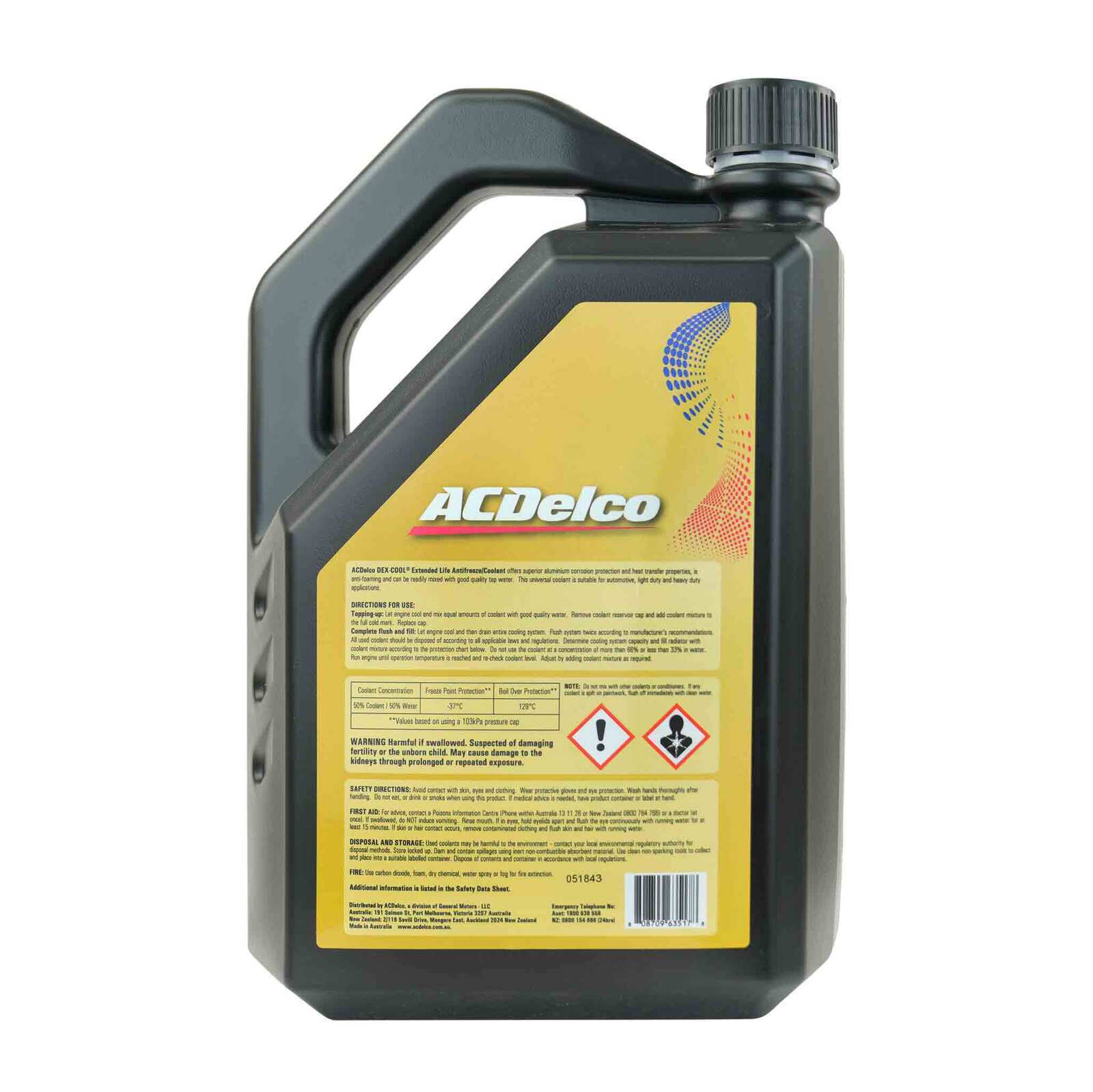

All late model manufacturers have chosen aluminium radiators as they simply outperform and outlast copper brass type radiators. Aluminium radiators do require specific coolant and regular flushing, see our warranty card instructions for more details.

Whatever orientation gives a longer tube length is best. If the radiator can be made wider than it is taller, then it should preferably be cross flow. If it is tall such as many early model cars, the rad should be vertical flow. This sees the longest water tube length possible and maximising core area inside of the space available in your vehicle or application.

Stray current is basically a ‘short’ or electrical fault in one of the vehicles electric circuits causing voltage to be present in the radiator coolant. In other words, the engine is trying to ‘earth’ to the body though the coolant as this is more conductive than the earths on the vehicle.

This stray current will begin to erode the cooling system including cylinder head(s), water pump, thermostat housing and of course the radiator. Often the radiator will show the first signs of this erosion as it is the lightest / thinnest material in the cooling system. Please see our warranty card instructions for more details.

As a rule, the standard engine fan in most cases will be effective at generating the required cooling airflow. However, engine fans sap power from the engine and quite often provide more airflow than is required at high engine speeds (except in the case of a Burnout vehicle where there is never too much airflow).

On the other hand, in traffic jams or slow vehicle use, the engine fan simply is not able to pull enough air. A thermo fan will offer consistent airflow at all vehicle speeds and result in more stable cooling.

Zip Tying the fans on through the rad core should be avoided at all costs. Tying off fans through the core will often result in premature failure of the core.

In relation to your 10” Fans we should compare their CFM rating against other sizes available. Some brands we see a single 16” flow three times that of a 10” fan!

Please call or email us and speak to one of our knowledgeable sales team members and they can walk you through ordering a custom unit to your specific requirements. We can also arrange to have your old radiator sent to us for assessment, we will measure it up and use it as a template to design a high performance version.

PWR Intercoolers

PWR currently manufacture two types of intercoolers.

- Air to Air – These intercoolers use ambient air to cool the charged air via a tube and fin construction.

- Water to Air – These intercoolers use water to cool the charged air which is then transferred through a stand-alone cooling system and exchanged with the ambient air through a low-temp radiator.

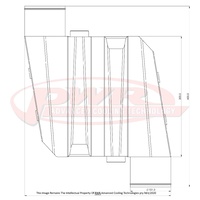

All intercoolers have the same job to do, to lower intake temperatures generated by forced induction. Whether it be turbocharged, or centrifugal supercharged, high intake temperatures are a major problem for the running of your vehicle. The choice between the two options really depends on the vehicles use and engine bay configuration. Air to Air intercoolers are most commonly used in intercooling applications when upgrading an OEM existing cooler or for a custom designed unit to fit in a certain space, our design capabilities are almost endless. Air to Air is great for street use, circuit racing track work, off road racing and drag racing. Water to Air is a compact and efficient unit when room is a factor or unable to fit a front mount. Having water to cool the charged air is perfect for high HP applications, drag racing, 4x4 and street use.

Tube and Fin is PWR’s choice of core design when it comes to intercooling. Our tube and fin technology allows for a wide range of styles and sizes. We offer the options of extruded tube and fin or a rolled tube and fin core configuration. Our extruded tube is a great all rounder that offers thermal efficiency without restricting the internal pressure drop and maintaining good air side pressure drop. Our Elite rolled tube and internal turb core option is for the customer that wants that edge over the competition. The result is extreme thermal efficiency while keeping the internal pressure drop to a minimum. The rolled tube also offers a massive weight saving over the extruded tube option.

PWR Oil Coolers

There are two main types of oil coolers made by PWR:

· Plate and Fin

· Tube and Fin

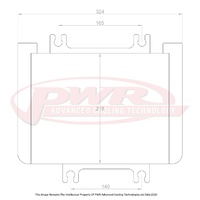

P&F (plate and fin) oil coolers are made in two basic groups – 19mm and 37mm plate widths. P&F is the lightest in construction and most efficient oil cooler relative to its area. The PWR P&F cooler is one of the most intricate designs on the market featuring dimpled plates and louvered fin. They offer reduced weight and increased efficiency yet strong construction.

Mainly used in transmission, power steering and differential cooling in road or race applications and can be seen under some V8 Supercars.

Yes, our P&F (Plate and Fin) 37mm coolers are used for this purpose and are also very efficient relative to their surface area. Plate widths have been increased which gives improved capacity and increased flow. These coolers feature a complex internal turbulator for added efficiency and strength.

Mainly used in engine oil cooling on modified street cars, tarmac race cars and any application where the cooler is fed cool air. Our 37mm P&F coolers can also be used for transmission fluid cooling as an extra HD option.

In-tank oil cooler refers to an arrangement where the plate and fin cooler is welded inside a radiator tank. The submerged cooler uses the engine radiator water to cool the oil. This is often done on Original Equipment (O/E) for its compact design.

In-tank P&F coolers offer more rapid, effective cooling relative to its area. In-tank oil coolers do not directly rely on constant airflow. We can often see these coolers put to good use in low-speed applications where airflow is limited. Another added advantage is often reduced oil cooler line length.

Due to the construction method, T&F (tube and fin) has the luxury of being able to be made in virtually any core dimension. A cooler can be requested as small as 50x50mm, right up to 1m Square! PWR T&F is a very robust construction while still offering high efficiency, high internal flow as well as a high rate of ambient airflow. T&F also has the luxury of being made in virtually any tank design, shape, or size. Outlet fitting size, position and angles are also virtually unlimited.

Often used in engine oil cooling to suit applications such as rotary engines, off road applications (where high amounts of debris may be present) and industrial applications.

SHOP NOW. PAY LATER. 100% INTEREST FREE

SHOP NOW. PAY LATER. 100% INTEREST FREE.png) BUY NOW. PAY LATER, No interest ever. Flexible terms.

BUY NOW. PAY LATER, No interest ever. Flexible terms.